Cold Storage Warehousing Solutions

The food and grocery logistics industries are growing rapidly. Thanks to new technologies, it’s now possible to transport frozen and refrigerated products safely across the country. One of the most crucial parts of the supply chain is cold storage warehousing. Products are preserved in temperature-controlled environments as low as -40°F. These freezing cold temperatures pose challenges that other types of warehouses don’t have to worry about, such as worker comfort and lift truck operation, all while still trying to maximize speed and efficiency.

Barclay Brand Ferdon works closely with cold storage warehouses to help them overcome some of the unique problems associated with storing food. Specific environments like these require specialized equipment that warehouse managers can rely on.

3PLs: Third Party Logistics Companies and Needs for Flexible Materials Handling Equipment

A 3PL, or third party logistics company, helps manufacturers, retailers and wholesalers with product fulfillment and distribution. One of the main reasons why retailers decide to work with a 3PL is because they value the flexibility. 3PLs can scale up and down as client needs change and accommodate a range of product types. Clients rely on this flexibility because, without it, they could face major problems in their supply chain any time something changes.

When thinking about adapting and restructuring, a lot of 3PLs focus on software to help keep them moving forward. Efficiency actually begins with the warehouse equipment and with the workers who are operating them. Barclay Brand Ferdon explores why it’s so important to focus on those things first before prioritizing technology.

Taylor-Dunn Warehouse Solutions

If you’re rethinking the equipment in your warehouse and whether you have the right materials handling solution, there is good news. Barclay offers Taylor-Dunn warehouse vehicles that allow you to move material, tow or carry a load, transport people, pick orders and more. These tools of the trade are excellent compliments to your forklift fleet that will help your company increase productivity and efficiencies.

NexSys Forklift Battery Charging Safety Precautions to Observe

NexSys industrial batteries by EnerSys are gaining popularity, and for good reason. These rugged, high-tech powerhouses offer lasting use and are optimized for opportunity charging, making them a smart choice when multiple shifts work around the clock. And while NexSys forklift batteries are as safe as they are reliable, it’s still important to take precautions during charging. Protect your team – and your investment – with these forklift battery charging safety tips from Barclay Brand Ferdon.

When To Replace Forklift Tires

Lift truck tires need to be replaced on a regular basis. As the rubber starts to wear away with use, it can impair the truck’s overall handling and performance. However, because tires don’t necessarily come with an expiration date, you have to rely on visual cues to let you know when it’s time for new ones. To help you better manage your fleet’s maintenance, review these tire care tips from the technicians at Barclay Brand Ferdon.

Forklift Telemetry | Managing Your Fleet Wirelessly

More and more warehouse managers are relying on lift truck fleet telemetry to help with everyday oversight. It allows them to monitor safety, efficiency and productivity around the entire warehouse—all in the palm of their hand. If you’re interested in integrating telemetry into your operations, Barclay Brand Ferdon offers a few key insights into the process below.

Understanding Lift Truck Fleet Telemetry

Telemetry is defined as a communications process by which data is collected and wirelessly transmitted to another piece of equipment. In this situation, it means the data from lift trucks can be sent to a manager’s laptop, computer or tablet for review at any time.

When they log on, managers can quickly get all the information they need to keep the warehouse running smoothly. The telemetry system can tell them…

When it’s time for individual truck maintenance

Information about accident occurrences

When employees need to complete their safety training

Labor requirements

Lift Truck Utilization – fleet “right sizing”

And more…

Essentially, telemetry gives managers the data they need to streamline and improve their operation in a simple and convenient way.

Benefits of Using Lift Truck Fleet Telemetry

Telemetry systems help managers be proactive about things going on around the warehouse. If it’s almost time for a lift truck’s regular maintenance, they can schedule it proactively to prevent additional repairs and downtime. Similarly, if an employee isn’t practicing proper safety procedures while operating a machine, they can intervene with additional training before an accident happens.

Other benefits of a lift truck fleet telemetry system include:

Maximize Productivity

Gives easy access to data at any time, so managers are always informed

Makes it easier to uphold safety and maintenance standards

Helps maximize ROI of your assets

Works with almost any lift truck

For example, at Barclay, we offer the Yale Vision telemetry system. Even though it’s designed by Yale, it’s compatible with all OEM brands of lift trucks as well. It is an option on new Lift Trucks or can be added to an existing fleet.

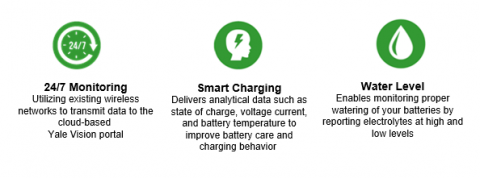

For electric lift trucks, fleet owners should consider industrial battery telemetry. Yale® Battery Vision is a solution that offers insight to better care for your batteries, an often overlooked but expensive asset. By having access to data, batteries can be monitored for better performance and longer life.

Improve Warehouse Efficiency Today

Whether you have 10 lift trucks or 100, adding telemetry will assist in managing your fleet to maximize productivity, improve safety and increase ROI. Contact Barclay Brand Ferdon and ask about getting lift truck fleet telemetry for your warehouse to take advantage of this powerful technology.

View a quick video.

Download white paper.