Cold Weather Calls for Emissions Testing

A brutal winter has sent shivers around the country and in New Jersey it’s not over yet. Cold weather and biting winds whistling through the warehouse environment may cause employees to batten down the hatches by closing normal venting outlets such as doors, windows and skylights. It opens the possibility of carbon monoxide (CO) levels rising to an unsafe level. Carbon monoxide, a colorless and odorless gas, is a by-product of all internal combustion engines. In this scenario, it’s time to have a Barclay technician check your emission levels and, if necessary, perform a tune up.

What’s That Sticker For? Annual Aerial Inspections Are A Must

In order to be in compliance with the OSHA General Duty Clause and ANSI standards, aerial platform inspections must be performed annually.

Section 6.7 of the ANSI Manual of Responsibilities reads as follows:

Choosing The Best Caster & Wheel

Do You Know the Best Caster & Load Wheel for Your Application?

Selecting the right casters and wheels for your Reach Truck, Order Selector, Turret or Pallet Jack can improve longevity, prevent downtime and increase productivity. Taking time to review the environment and operation can easily decide the best Load Wheel for your specific application. Selecting the best overall caster and wheel choice will be based on a few factors that will ensure smooth operation and longevity.

Blue Light: Blazing The Trail For Safety

Here at Barclay, we pride ourselves on promoting the highest level of workplace safety through our OSHA compliant safety training programs and safety equipment.

While we are well aware that OSHA holds employers accountable for maintaining a safe and healthful work environment, we believe that employee safety is a shared responsibility, to be accomplished through safety awareness and diligence by all employees.

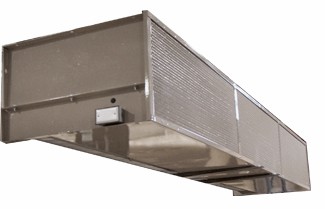

Industrial Warehouse and Plant Facilities benefit from installing Air Curtain/Door Technology

What is an Air Door/Curtain?

An air door, also called an air curtain, employs a controlled stream of air aimed across an opening to create an air seal. This seal separates different environments, while allowing a smooth, unhindered flow of traffic and unobstructed vision through the opening.

Forklift & Forklift Battery Recycling

Barclay would like to remind our customers of our FREE pick-up of all scrap equipment for recycling. We will pick up and dispose of your old industrial forklift batteries and equipment absolutely FREE!

Call Us to pick up your old:

Industrial batteries

Forklifts

Aerial Equipment

Lucky You – There is More Than One Way to Go Green This St. Paddy’s Day!

Shamrock Shaped 3 Easy Tips To Go Green This St. Patrick’s Day!

Going green is more important now more than ever before. Let Barclay make it easier to go green. A properly tuned and maintained engine can reduce harmful emissions. Making the environment cleaner and safer for all the little shamrocks and leprechauns in your life!

Use these 3 tips to Go Green this St. Patrick’s Day!