Protecting Your Assets in the Warehouse and Plant

For any material handling operation to be successful, safety must be the number one priority. Yet time and space constraints often prompt warehouses and plants to create narrower aisles and taller pallet racks to store more product, significantly upping the risk of workplace accidents and injuries.

That’s why these businesses need comprehensive warehouse pallet racking protection systems. To teach you more about these safeguards, New Jersey-based Barclay Brand Ferdon outlines the types of solutions that will help maximize your gains by enhancing the safety of your workplace.

Truck Mounted Forklift Guide

For a commercial business to succeed, you’ll not only need to offer quality products but also have the means to transport them to your customers safely and efficiently. When this second task arises, many businesses opt to hire outside assistance, increasing costs and limiting flexibility and convenience. Those companies who choose to maintain their own fleet of delivery trucks then need to deal with how the product is unloaded at the customer’s location or jobsite. Delivering loads where equipment is not readily available and terrain may not be easily maneuverable provides a challenge. But an ideal solution is to attain a truck-mounted forklift so staff can load and unload goods wherever and whenever they need to. To help you learn more about this material handling solution, Barclay Brand Ferdon explores the logistics of truck-mounted forklifts.

Benefits of Quality Forklift Service Technicians

Even though there are a lot of forklift technicians out there, they don’t all have the same level of expertise. And, unfortunately, when technicians aren’t fully qualified to service your fleet, it shows. That’s why it’s so important to hire trained professionals who know exactly what they’re doing, like the team at Barclay Brand Ferdon. Here are the top four benefits of working with well-trained lift truck service technicians.

When Do You Need an EX Rated Forklift or Pallet Jack?

Facilities where flammable and/or volatile materials are present require specific equipment designed to minimize the risk of open fire and explosions. This equipment is Explosion Proof (EX) rated to strictly control temperature, static and other factors that cause dangerous explosions. Should your business invest in EX rated forklifts? The material handling equipment experts at Barclay Brand Ferdon explain how EX rated forklifts improve safety and where they should be used.

How to Maintain Your Electric Pallet Jack

For many warehouses, moving materials is a 24/7 job. But as long as you keep your electric pallet jacks in good working condition, you’ll be ready for whatever comes through the dock doors. Anytime you need maintenance, repairs or replacement parts, call on the service technicians at Barclay Brand Ferdon to help extend the life and maintain the safety of your pallet jacks.

Your Business is Logistics, Not Lift Trucks: Short-Term Rentals or Long-Term Solutions

Purchasing a lift truck isn’t the right path for every warehouse, every time. In some cases it makes more sense to invest in owned forklifts, but often times, businesses find that renting can make better financial sense. If you’re in need of reliable lift trucks for your fleet but aren’t sure whether to buy or rent, Barclay Brand Ferdon shares some insights into how to make the best decision for your business.

Is Cheap Lift Truck Service Really Less Expensive in the Long Run?

When deciding on which lift truck service provider to call, be careful not to let cheap hourly labor rates blind you. Opting for lower rates may appear to be the cheapest route, but it’ll cost you in the long run. As they say, you get what you pay for. The next time your lift truck breaks down or needs maintenance, call on the experts at Barclay Brand Ferdon.

Cheap Service Isn’t So Cheap After All

Would you choose a low hourly service rate if it meant higher overall costs and exposure to liability risks for your company? Understand the “true” cost of that “cheap” hourly service rate and the other factors you should consider.

Reduced Repair Times

By using Factory Technicians that undergo continuous training and testing, you have the best opportunity to reduce time of repair. A technician who knows the equipment and is trained in diagnostics can make a big difference in repair costs. Consider this: A 20% difference in hourly rate for a 3 hour repair that takes 4 hours will cost you more, not less.

Equipment Downtime

An OEM lift truck service provider that invests in technologies and parts inventories can offer better response time, high fill rate on parts availability, OEM quality parts and proper Operational Maintenance to prevent breakdowns. Lost productivity due to equipment downtime can be costly.

“Right Size” your fleet

Excessive equipment and the potentially corresponding labor is extremely costly!! The cost of just (1) additional “underutilized” truck can be huge. A responsible Materials Handling Service provider should offer you continuous analysis and management reporting to prevent overspending and inefficiencies.

Stay in Control

A true partner helps you understand your “total” Fleet Maintenance Expense and will guide you to emerging technologies that may help reduce costs over the long run.

Reduce your Risk

A Service Technician will spend time within your operation and alongside your employees. Accidents can happen. Reduce your risk by selecting a partner with adequate, responsible liability Insurance Coverage. You will be surprised by what that low hourly rate doesn’t cover.

Improve Safety & Reduce Product Damage

A good Service provider also provides on-going OSHA Operator Safety Training programs and thorough Equipment Safety Inspections. Many companies do not perform all that the manufacturer requires during a regular operation maintenance interval.

Protect Your Investment

A lift truck is a big investment, choosing the right Service Provider and Maintenance Plan is essential in protecting that investment as well as assuring the lowest overall cost over the life of the equipment.

To learn more about maintenance programs at Barclay, contact a representative today.

Good Operational Maintenance Can Save Your Company More than Money

A lot of companies don’t realize just how valuable a planned operational maintenance program can be. Not only can it help keep your lift trucks, dock levelers, overhead doors and other equipment working properly, but it can also impact your operations in many other ways. In this blog post, Barclay Brand Ferdon explores what those benefits entail.

Introducing NexSys Industrial Batteries

You’ve carefully selected the best equipment for your business. But have you outfitted that equipment with batteries designed specifically for the demands of your work environment? With a rugged build and technologies to suit multi-shift operations and public spaces alike, EnerSys NexSys industrial batteries available from Barclay Brand Ferdon deliver the power necessary to keep you up and running. Learn more about these convenient batteries to determine if they’re the best option for your equipment.

Gain an Edge: Yale Pallet Jacks with the Direct Store Delivery Package

With a host of efficiencies for manufacturers and retailers alike, Direct Store Delivery (DSD) has become an increasingly popular way for businesses to supply stores with their products. By bypassing retail distribution centers, suppliers can speed delivery times for perishable or high demand products and gain more control over merchandise replenishment and displays at the retail level. Direct Store Delivery has been adopted by food, beverage, personal care as well as many different service supply industries.

The one challenge that DSD strategy poses for truck drivers is the availability of necessary equipment to unload product from trailer into store. Reliance on store owned equipment is not ideal for quick and efficient unloading and poses challenges to meeting a full day of truck deliveries in a timely fashion.

Always keeping a finger on the pulse of customer needs, Yale responded to the growth of DSD with electric pallet jacks equipped with an industry exclusive “Direct Store Delivery Package”, a set of features optimized specifically for the demands of a DSD distribution strategy. Learn more about what the Direct Store Delivery Package can offer with this overview from Barclay Brand Ferdon.

What Makes DSD Pallet Jacks Unique

In addition to the standard features of motorized Yale pallet jacks, the DSD models come outfitted with the following:

Exclusive handle design to give operators complete control over the pallet jack

Movable load bracket and single-fork configuration to accommodate loads of various shapes and sizes

Load retention strap to secure each load, making it ideal for items that require special handling

One-hand throttle activation that enables excellent visibility and allows operators to work closer to the truck

Mid-mount steer handle and creep speed functionality for use in narrow aisles and tight spaces while moving and delivering products

Fully optimized for the needs of delivery truck drivers, these pallet jacks support fast loading and unloading and energy efficiency and offer a rugged, flexible design built for the productivity mindset essential to DSD operations.

The Advanced Performance Power System

The Direct Store Delivery package for Yale pallet jacks is a product of innovation boasting a host of award-winning features. As an industry first, we’re seeing a UL-recognized, factory-installed lithium-ion battery used to power a pallet truck—as opposed to the conventional lead acid battery configuration.

This is significant, because lithium-ion batteries are much more energy efficient and easier to maintain. There are no spills, fumes or cleaning necessary for a lithium-ion battery, which means less oversight and more productivity.

Streamline DSD Operations Today

Ready to learn more about the benefits of Yale’s Direct Store Delivery Package? Contact Barclay Brand Ferdon at 908-561-2100 or contact us online – a member of our team will answer your questions and help you choose the pallet jacks that can help your business save time and money.

Our Process for Pre-Owned Warehouse Equipment

While used warehouse equipment is more affordable than purchasing new equipment, if not purchased from a reputable provider, it can often cost you more in the long run. You can count on Barclay to supply the safest, most reliable products that will be matched to your materials handling application and budget. From start to finish, here’s a behind-the-scenes look at our pre-owned equipment process that explains how we source and prepare each piece of used equipment before delivery to our customer.

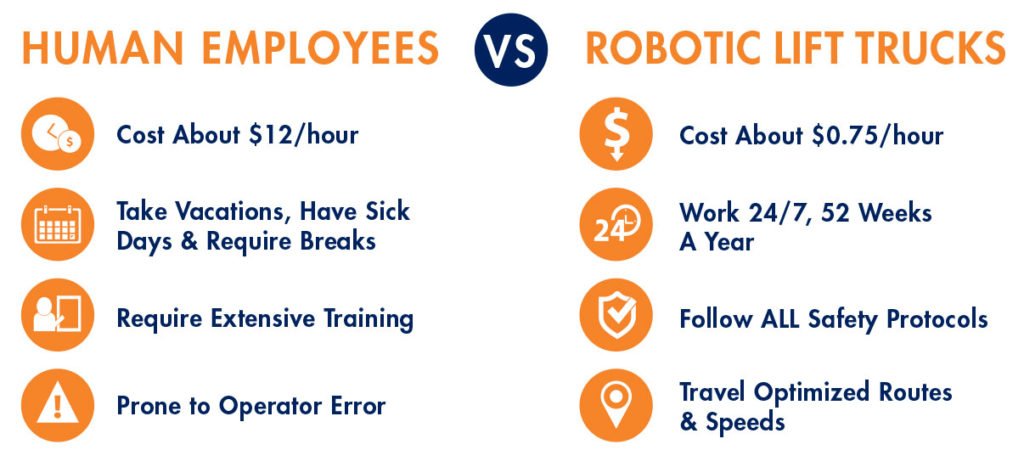

Robotic Lift Trucks For Automated Materials Handling

Increasing productivity in your warehouse or distribution center could be as simple as automating repetitive picking tasks to free up your workers and maximize labor efficiency. Robotic lift trucks make automated material handling a reality! Barclay Brand Ferdon is a material handling equipment company in South Plainfield, New Jersey, serving Central and Northern New Jersey. We have the equipment you need to streamline your operation, including the latest robotic lift trucks on the market.

Task Automation

Automation promises to bring new levels of efficiency and productivity to distributors in a wide array of industries. However, optimizing material handling operations and driving sound ROI starts with automating the right processes for your business. Look for processes that are:

Repetitive, with little variation

Subject to high employee turnover

Troubled with other inefficiencies

Automation Benefits

It just makes sense to automate your warehouse or distribution center with robotic lift trucks once you realize all the benefits you’ll enjoy. Automation with a robotic lift truck offers:

An infrastructure free operation, because it uses your existing structural features, such as walls, racks and columns to self-locate and navigate it

Rapid deployment, because it can run with zero, partial or full integration with your warehouse management systems.

Scalability, because you can start small and expand with your operational needs.

Flexibility to accommodate your changing operational needs by allowing you to switch to manual operating mode with the simple touch of any button.

Where Does It Make Sense In Your Warehouse Or Distribution Center?

Dock to Stock: A robotic lift truck can take over the long hauls from the receiving dock to the stock room.

Low-value Added Tasks: A robotic lift truck can execute low-value added tasks, which effectively frees up staff and helps lower labor expenses.

Stock to Dock: A robotic lift truck can also run merchandise from the stockroom to the loading dock. Integrate your warehouse management systems to provide visibility of load movement and increase accuracy.

Long Load Transfers: A robotic lift truck can easily transfer loads over long distances without taking up any of your workers’ valuable time.

Increasing Productivity: Dispatch multiple robotic lift trucks simultaneously and increase productivity even further.

Get Automated

We help you re-think your warehouse! Advances in technology and guidance systems have provided a new generation of robotic lift trucks. For more information on how automation helps your operation, contact us at 908-223-8580 today!

- « Previous

- 1

- 2

- 3

- Next »

Categories

- Tires (3)

- Used (1)

- Choosing Equipment (1)

- Efficiency (6)

- Training (4)

- Warehouse Carts (3)

- Cold Storage (2)

- Racking (1)

- Attachments (3)

- Electric (3)

- Company News (1)

- Batteries (4)

- Forklifts (2)

- Case Studies (1)

- Robotic Forklifts (2)

- Aerial Lifts (2)

- Product News (7)

- Barclay Blog (24)

- Forklifts (6)