Whether you work in warehousing, logistics, manufacturing, pharmaceuticals, food production, or distribution, maneuvering a forklift (or several) is likely part of your business’ day-to-day operations. While these pieces of machinery offer a host of advantages, such as improving your workplace’s efficiency, they must be operated with extreme care and skill to avoid injuries, damaged goods, and other unfortunate outcomes. Here, Barclay Brand Ferdon offers five rules and tips to ensure forklift safety at your job site.

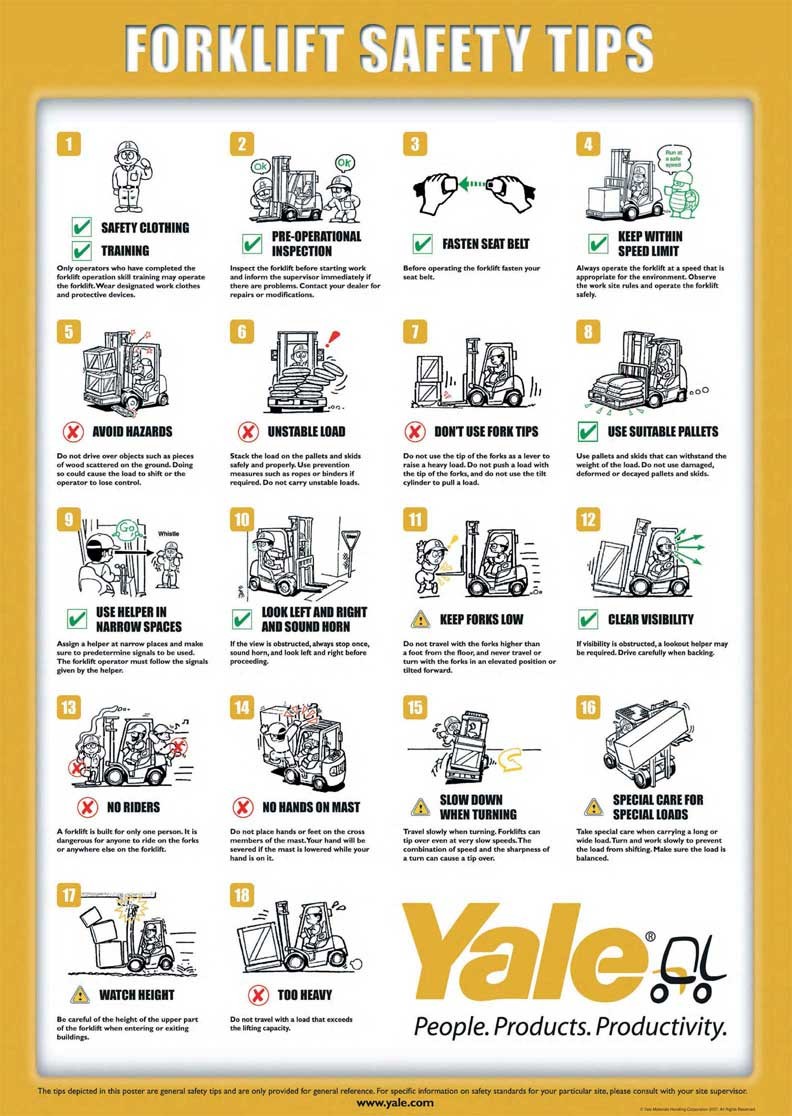

1. Prioritize Training

Occupational Safety and Health Administration (OSHA) standard 29 CFR 1910.178(l)(3)(i) requires that only trained operators drive forklifts in your facility and that your company must provide the training necessary to maintain compliance. Topics should include information related to the forklifts in your fleet and their safe use within the workplace. To ensure your team receives the training they require, look for programs that include OSHA and ANSI standards and rules, best practices for safe operation, and other important elements.

2. Know the Floor and Facility

When operating a forklift, all workers must know your facility like the backs of their hands, including every twist, turn, and potential obstacle that might arise. They should also be well-versed in the layout of your facility, where certain products are kept, and the appropriate zones for loading and offloading – along with any special procedures for each area.

One way to help promote forklift safety in this manner is to develop a floor-marking system with easy-to-follow signs and labels. You can post aisle markers, forklift procedure instructions, safety reminders, and more, ensuring that both pedestrians and vehicle operators can clearly see all signs – especially at intersections within your facility. According to OSHA standard 29 CFR 1910.144(b)(2), red markings should be used to identify fire-related hazards, while yellow markings signal to use caution.

3. Use A Spotter In Narrow Spaces & Look Both Ways

Obstructed vision is one of the leading causes for forklift accidents. Ask for someone to help you when working in a narrow space. Use predetermined signals to ensure solid communication and safety. Always look right and left before proceeding. If you can’t see, sound your horn to let others know you are coming so they can be out of the way.

4. Be Able to Identify Hazards

Operating a forklift requires workers to always anticipate any hazards that are present or may occur. For example, if a load is not secured, it could fall off the forklift and injure the driver and/or other employees. And if excessive speed is used or a load is not properly balanced, the forklift could potentially tip over. Beyond awareness of these specific hazards, workers should be trained to watch out for the following:

- Obstructions

- Potential overhead obstacles

- Uneven or rough surfaces

- Pedestrians

- Floor markings that are incorrect or missing

5. Keep Forks Low & Ensure Clear Visibility

Even if you are only going a few feet, it is important to keep forks low. Never travel with forks in an elevated position or lifted higher than a foot off the floor. It also never hurts to have a lookout helper if vision is not 100% clear, especially when reversing!

6. Handle Hazardous & Unstable Loads with Care

Certain loads will naturally be at greater risk for falling off the forklift than others, meaning operators must know how to handle them with extreme care. Forklifts have an approved maximum capacity, which should always be adhered to, and the load should always be strapped in place before operating the vehicle. Other helpful tips in this area include:

- Don’t use damaged, warped, or decaying pallets or skids

- Balance the load evenly on both forks

- Loads will balance most stably near the mast, so be sure to stack them there

- Ensure the load does not obstruct the driver’s view; if it does, operate in reverse

7. Develop a Strong Communication Plan

While forklift operators may be responsible for loading and offloading cargo, all employees in the facility must be aware of forklift operating procedures and safety measures. Developing a strong communication plan, consisting of written information, helpful photos, and instructional videos is one of the best ways to ensure everyone in the facility can work safely around forklifts.

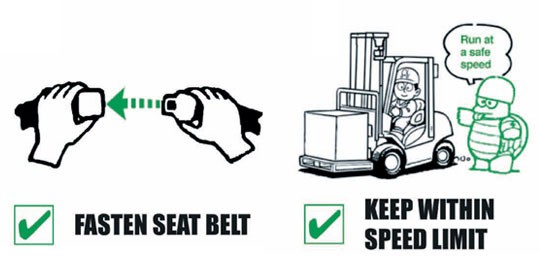

8. Fasten Your Seat Belt & Stay Within The Speed Limit

Much like a car or truck, forklifts improve efficiency and allow us to move more products quicker. They also require the same easy steps to keep the operator safe. Always remember to fasten your seat belt. A lot of accidents can be avoided with a simple “click!” Also be mindful of your speed and surroundings. Observe the rules of your work site and operate the forklift appropriately.

9. Use Proper Gear, Training & Inspections

Safety Clothing & Training

Only operators who have completed the forklift operation skill training may operate the forklift. Wear designated work clothes and protective devices.

Pre-Operational Inspection

Inspect the forklift before starting work and inform the supervisor immediately if there are problems. Contact Barclay for repairs or modifications.

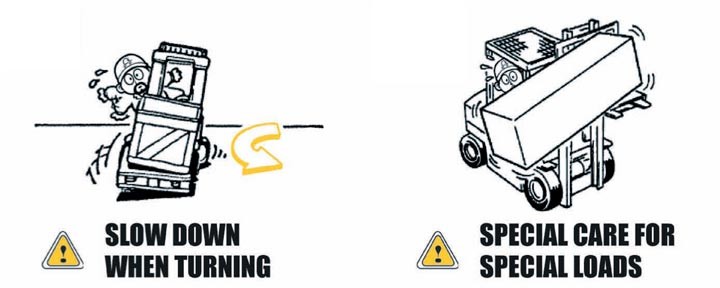

10. Turn Slowly & Take Special Care With Special Loads

Be aware of the height of the forklift when entering or exiting buildings and pay attention to the lifting capacity of your lift truck. These steps will help to avoid product and equipment damage, as well as employee injury.

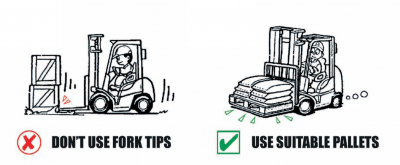

11. Don’t Use Fork Tips & Use Suitable Pallets

The point of a forklift is to safely move products up or down or across a warehouse facility. Improper loading techniques cannot only damage product but can seriously injure the operator or someone else. Do not use the fork tip as a lever to raise a heavy load or to push a load, and do not use the tilt cylinder to pull a load. This can result in costly damages to the forklift. Use pallets that can stand the weight of the load. Do not use damaged, deformed or decayed pallets and skids.

12. Do Not Allow Riders & Keep Your Hands Off The Mast

It is very important that only the operator rides in the seat of the forklift. There should be no other passengers on the forks or anywhere else. Also keep hands and feet inside the forklift at all times, as a lowered mast could sever hands.

Learn More about Forklift Safety

Providing proper training for every forklift operator is the best way to maintain a safe facility for all. For more information about forklift safety, contact Barclay Brand Ferdon. We offer a variety of safety programs, including on-site training and our Train the Trainer program that prepares participants to lead their own future in-house programs. In addition to our safety training, we offer new, used and rental material handling equipment as well as warehouse solutions such as pallet racking.